Rotary drum granulator

Rotary drum granulator is a critical machine in fertilizer production process.Its quality decides directly the efficiency and quality of end product.Pellets produced via granulator machine are a little more dense,and more sepherical than other agglomeration methods.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Overview

Quick Details

Key Selling Points:Long Service Life

Applicable Industries:Manufacturing Plant, Energy & Mining

Showroom Location:Egypt, Turkey, Saudi Arabia, Indonesia, India, Thailand, UAE, Algeria, South Africa, Nigeria, Uzbekistan

Application:Fertilizer coating Machine

Raw material:Chemical fertilizer ,organic fertilizer

Capacity:10000-300000T/Y

Final product:Ball Shape Fertilizer

Material:Carbon Steel Made

Working method:Agglomerate

Application Scope:NPK Fertilizer Industry ,organic fertilizer industry

Feature:High Working Efficiency

Pellet diameter:Fertilizer:3-5mm

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Egypt, Turkey, Viet Nam, Brazil, Saudi Arabia, Indonesia, Pakistan, India, Thailand, Kenya, UAE, Colombia, Algeria, Sri Lanka, South Africa, Ukraine

Certification:ISO9001

Packaging & Delivery

Packaging Details Standard container

Port Qingdao ,Shanghai ,Tianjin

Lead Time:

| Quantity(Sets) | 1 - 10 | >10 |

| Est. Time(days) | 20 | To be negotiated |

Video Description

Product Overview

Rotary drum granulator

Rotary drum granulator is a critical machine in fertilizer production process.Its quality decides directly the efficiency and quality of end product.Pellets produced via granulator machine are a little more dense,and more sepherical than other agglomeration methods.

1 How rotary drum granulator works?

Its main work method is reunited wet granulation, with the founction of a certain amount of water or steam, the powder or fine type raw materials feed into the drum reunion into pellets with the rotation of cylinder.

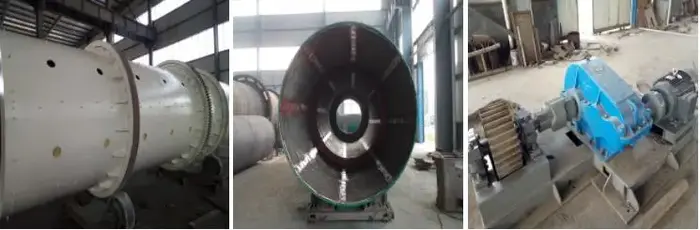

2 The component of rotary drum granulator

1 Raw material feed chute

2 Riding ring

3 Ring gear and ring gear guard

4 Drive assembly

5 Lining

6 Discharge part

7 Exhaust discharge system

FEATURES AT A GLANCE

1.It is used for producing high,medium,low concentration of compound fertilizers,organic fertilizer and other kinds of fertilizer,it can also be used for other field,such as agricultural,mining and chemical industry for various products.

2 The inner wall of the granulator uses a special customized rubber lining,it has the advantage of anti-corrosion,effectively

prevent high temperature and anti-rusty.

3. The granulation rate is high, the end product is good-quality with more dense with perfect surface.

PRODUCT SPECIFICATIONS

| Model | Size | Capacity(t/h) | Inclination (degree) | Rotate speed (rpm) | Motor power(kw) |

| ZL1405 | φ1.4mX5m | 3-4 | 2-2.5 | 13.5 | 11 |

| ZL1606 | φ1.6mX6m | 5-8 | 2-2.5 | 12 | 15 |

| ZL1806 | φ1.8mX6m | 8-10 | 2-2.5 | 11.5 | 18.5 |

| ZL2008 | φ2.0mX8m | 10-15 | 2-2.5 | 10.2 | 22 |

| ZL2208 | φ2.2mX8m | 16-20 | 2-2.5 | 9.7 | 30 |

| ZL2408 | φ2.4mX8m | 20-22 | 2-2.5 | 9.7 | 45 |

| ZL2610 | φ2.6mX10m | 22-30 | 2-2.5 | 9.2 | 55 |

Disc granulator

1 .How disc granulator works?

Disc granulator work by tumbling raw material on a rotating disc.The fines or seed pellets become stacky with the water or steam and pick up feeding raw materials as they tumble,this allows the pellets to grow to the desired size,at which point they exit the granulator and are sent to the rotary dryer for following process by the belt conveyor.

2 The components of disc granulator

2.1 Disc

2.2 Drive assembly

2.3 Scraper blade and its support

2.4 Support base

2.5 Adjustment device

3 Characteristics of disc granulator

3.1 The rate of pellets is higher and little recycle.,which make it more efficient in making granules.

3.2 Disc granulator requires less maintenance and have fewer parts that need placing.

3.3 It can be used widely for many industries,such as chemical industry,mining industry and agricultural industry.

| Model | Disc diameter(mm) | Capacity(t/h) | Disc obliquity(°) | Motor power(kw) |

| DP2400 | φ2400 | 1-2 | 44-55 | 7.5 |

| DP2600 | φ2600 | 2-3 | 44-55 | 7.5 |

| DP2800 | φ2800 | 3-4 | 44-55 | 11 |

| DP3200 | φ3200 | 4-5 | 44-55 | 11 |

| DP3500 | φ3500 | 5-6 | 44-55 | 15 |

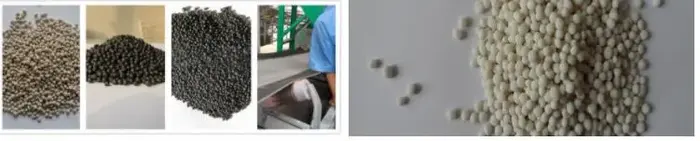

Final granules produced by our machines

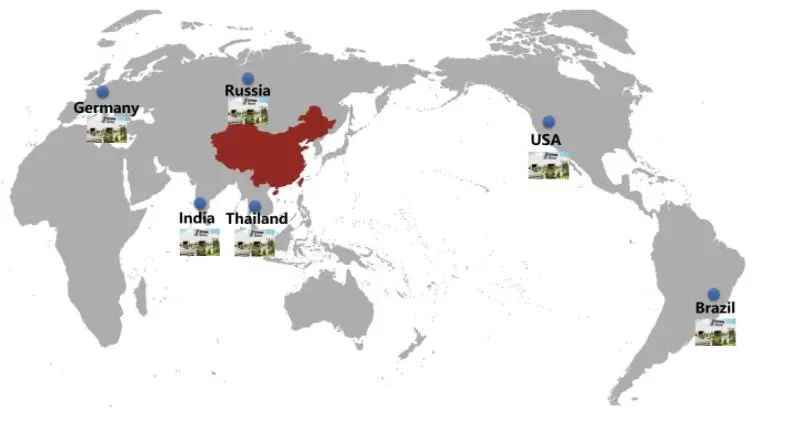

SALES AND SERVICE NETWORK

Successful Project

SIMILAR PRODUCTS

Delivery machines to our clients

FAQ

1. Are you a manufacturer factory?

A: Yes, we are the professional manufacturer of the fertilizer machines for 30 years.

2. Could you provide the installation, commssioning, training or other kinds service?

A: Yes, we could arrange professional engineers to install the machines ,train your workers and test run the complate production

line until your workers handle the operation; in addition ,we can supply the fertilizer fomulars for free.

3.Do you have customers near your factory, then can we visit the running fertilizer machines line?

A:Yes, there are many clients near our factory, we could take you to check the running fertilizer machines line.

4.Do you have experience in exporting, installing and traing the NPK fertilizer machines line in Africa, Southeast Asia, Middle

East, South Asia, central Asia, Central America?

A:Yes, we have rich experience. Our fertilizer machines had exported to Saudi Arabia, India, Indonesia, South Africa, Nigeria, Dominica, Kazakhstan, Spain, Vietnam and other countries.

Contact Our Team

PRODUCTS CENTER

- Organic Fertilizer Equipment

- Compound Fertilizer Production Line

- Urea Production Plant

- Water Soluble/Controlled Release Fertilizer Equipment

- Blending Fertilizer Equipment

- Amino Acid Equipment

- Crushing Equipment/Mixing Equipment

- Granulation Equipment

- Rotary Dryer/Spray granulation dryer

- Rotary Cooler

- Fermentation Equipment

- Coating Machine/Screening Machine

- Dust Removal Equipment

- Auxiliary Equipment

CONTACT US

Contact Number

0086-18864836668

-

Sales Manager:

Johnny Cheung

-

Contact E-mail

-

Wechat

JohnnyZhang1987

-

Fax

86-0538-8761127

-

Address

Taishan Industrial Park, Tai'an City, Shandong Province

PRODUCTS

PRODUCTS Contact Us

Contact Us