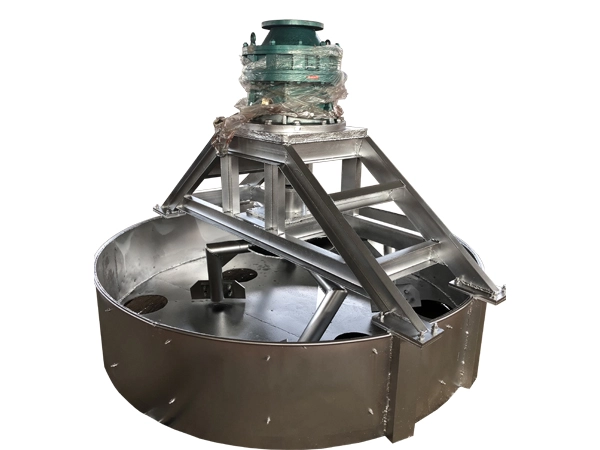

Vertical mixer

Production capacity: 2-10 tons/hour Applicable materials: mixing of various materials, all kinds of dry and wet materials, small particles, semi-wet materials, etc. Application scope: organic fertilizer production, inorganic fertilizer production, chemical metallurgy, mining, building materials and other industries

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Product introduction

This machine is a new vertical disc mixer, which consists of mixing plate, discharge port, mixing arm, rack, gearbox and transmission mechanism. The characteristic of the machine is that the output shaft end of the reducer drives the stirring main shaft to operate, and the stirring shaft has fixed stirring teeth, and the stirring shaft drives the stirring teeth to mixing the material sufficiently. The mixer has long service life, energy saving, small volume, fast stirring speed and continuous working. The machine is mainly used for the mixing of raw materials. The inside can be lined with polypropylene plate or stainless steel plate. It is not easy to stick material and wear resistance. The cycloid pinwheel reducer make the machine has the characteristics of compact structure, convenient operation, uniform mixing, and convenient discharge and transportation.

Performance characteristics

1. The inner tray is lined with polypropylene plate or stainless steel plate, so it is not easy to stick to the material. durable.

2. The vertical mixer adopts a cycloid pinwheel reducer, which has the characteristics of compact structure, convenient operation, uniform mixing, and convenient discharge and transportation.

3. The vertical mixer feeds from the top and discharges from the bottom, with a reasonable structure.

4. The airtightness between each joint surface is very tight, and the machine can run more smoothly.

5. High mixing efficiency, small floor space and low operating noise.

Working principle

The vertical disc mixer is a new type mixing equipment for continuous running. It is mainly used in organic fertilizer, compound fertilizer and thermal power plant, and can also be used in chemical, metallurgy, mining, building materials and other industries. We adopt special wearing alloy for the spiral blade for longer service time. The disc mixer feeds from the top and discharge from the bottom with reasonable structure. it is widely used in the fertilizer processing industry, and we supply the turn-key basis fertilizer project start from design, producing, installation, debugging and technical training. The electrical motor drives the reducer, and the reducer drives the main shaft, and the main shaft drive the mixing plate to mix the materials.

Product Parameter

Model | Capability(t/h) | Dish Height(mm) | Stirrer Diameter (mm) | Feeding texture(mm) | Rotate Speed(r/min) | Power(KW) | Weight(t) |

LJ1800 | 3-5 | 430 | Φ1800 | <50 | 11 | 5.5 | 1.2 |

LJ2000 | 4-6 | 430 | Φ2000 | <50 | 12 | 7.5 | 1.7 |

LJ2500 | 6-8 | 450 | Φ2500 | <50 | 12 | 11 | 1.8 |

LJ2800 | 8-10 | 500 | Φ2800 | <50 | 12 | 15 | 2.1 |

Contact Our Team

PRODUCTS CENTER

- Organic Fertilizer Equipment

- Compound Fertilizer Production Line

- Urea Production Plant

- Water Soluble/Controlled Release Fertilizer Equipment

- Blending Fertilizer Equipment

- Amino Acid Equipment

- Crushing Equipment/Mixing Equipment

- Granulation Equipment

- Rotary Dryer/Spray granulation dryer

- Rotary Cooler

- Fermentation Equipment

- Coating Machine/Screening Machine

- Dust Removal Equipment

- Auxiliary Equipment

CONTACT US

Contact Number

0086-18864836668

-

Sales Manager:

Johnny Cheung

-

Contact E-mail

-

Wechat

JohnnyZhang1987

-

Fax

86-0538-8761127

-

Address

Taishan Industrial Park, Tai'an City, Shandong Province

PRODUCTS

PRODUCTS Contact Us

Contact Us