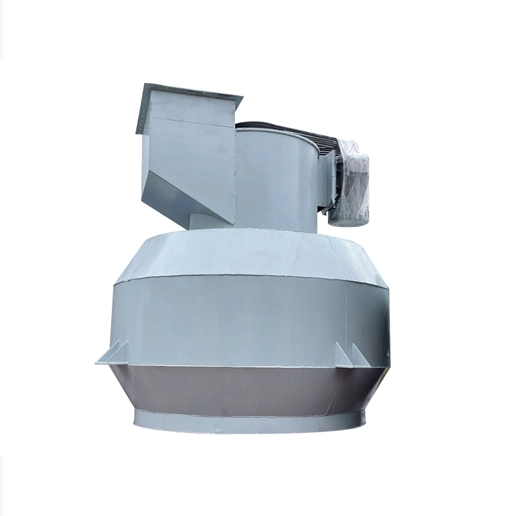

Raymond mill

Raymond pulverizer is a commonly used grinding equipment. It adopts advanced grinding technology and is designed and manufactured on the basis of Raymond mill in the same industry. It is suitable for fine powder processing of raw material ore, gypsum ore, coal and other materials. Operation.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Overview

Raymond pulverizer is a commonly used grinding equipment. It adopts advanced grinding technology and is designed and manufactured on the basis of Raymond mill in the same industry. It is suitable for fine powder processing of raw material ore, gypsum ore, coal and other materials. Operation.

Applicable materials: suitable for barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorite, etc.

The whole structure of Raymond mill is composed of main machine, analyzer (powder separator), pipeline device, blower, finished cyclone separator, etc. The main machine is mainly composed of frame, inlet volute, blade, grinding roller, grinding ring , Housing and motor, etc.

The working principle of the product, after the material is crushed to the required particle size, the material is sent to the storage hopper by the elevator, and then sent to the main grinding chamber uniformly and quantitatively by the vibrating feeder; due to the centrifugal force during rotation, the grinding roller outwards Swing, the shovel pressed tightly on the grinding ring scoops up the material and sends it between the grinding roller and the grinding ring, and the grinding roller achieves the purpose of grinding the material due to the rolling of the grinding roller. The ground powder is taken away by the airflow of the fan. After being classified by the analyzer, the powder that meets the fineness will enter the large cyclone collector with the airflow through the pipe, and be separated and collected, and then discharged through the powder pipe to become the finished powder. In the grinding chamber of the Raymond mill, there is a certain amount of moisture in the material to be ground. During grinding, heat is generated, the water vapor evaporates, and the pipe connections of the whole machine are not tight. The mill works under negative pressure, and the increased air flow is discharged into the dust collector through the residual air pipe, and then discharged into the atmosphere after being purified.

Product advantages:

1. Strong complete set

Raymond pulverizer is a vertical structure with a small footprint and a strong complete set. Whether it is from the rough processing of raw materials, conveying or powdering and packaging, it can be an independent production system.

2. Higher screening rate

Compared with other pulverizers, Raymond pulverizer has a higher sieving rate, as high as 99%, which is difficult to achieve by other pulverizing equipment.

3. Good wear resistance

The main components of Raymond pulverizer are cast with high-quality materials, and the craftsmanship is exquisite, which ensures that the whole set of Raymond pulverizer equipment has high operating efficiency and good wear resistance. The main body of Raymond pulverizer has improved the traditional method and has The Hemeihuajia has undergone structural transformation that is conducive to stability, so that its transmission is stable and its operation is reliable.

4. Low failure rate and easy maintenance

The electrical system adopts centralized control, and the grinding workshop of Raymond mill can basically realize unmanned operation, reduce manual operation cost, and convenient maintenance.

5. Good grinding effect

The entire air flow system of the Raymond mill is a closed cycle, and it circulates under positive and negative pressure. There is a certain water content in the material to be ground in the mill. The heat generated during grinding causes the gas in the mill to evaporate and change the air flow. At the same time, because the joints of the pipes of the whole machine are not tightly sealed, the outside air is sucked in, which increases the circulating air flow. Therefore, the balance of air flow is achieved by adjusting the residual air pipe between the fan and the main engine, and the excess gas is introduced into the bag filter to collect the fine powder brought in by the residual gas, and the residual gas is purified and discharged.

technical parameter

model | 4525 | 4119 |

Feeding size(mm) | ≤30 | ≤25 |

Finished product size(mm) | 0.173-0.044 | 0.173-0.044 |

Shift production with different material fineness(t) | 16-176 | 8-78 |

Central shaft speed(r/min) | 82 | 105 |

Diameter of grinding ring(mm) | 1770 | 1400 |

Diameter of grinding roller(mm) | 450 | 410 |

Height of grinding roller(mm) | 250 | 190 |

Main motor(kw) | Y315M-4-132 | Y280S-4-75 |

Fan motor | Y315M-4-132 | Y280S-4-75 |

Analyzer motor | YCT250-4A-18.5 | YCT200-4B-7.5 |

Contact Our Team

PRODUCTS CENTER

- Organic Fertilizer Equipment

- Compound Fertilizer Production Line

- Urea Production Plant

- Water Soluble/Controlled Release Fertilizer Equipment

- Blending Fertilizer Equipment

- Amino Acid Equipment

- Crushing Equipment/Mixing Equipment

- Granulation Equipment

- Rotary Dryer/Spray granulation dryer

- Rotary Cooler

- Fermentation Equipment

- Coating Machine/Screening Machine

- Dust Removal Equipment

- Auxiliary Equipment

CONTACT US

Contact Number

0086-18864836668

-

Sales Manager:

Johnny Cheung

-

Contact E-mail

-

Wechat

JohnnyZhang1987

-

Fax

86-0538-8761127

-

Address

Taishan Industrial Park, Tai'an City, Shandong Province

PRODUCTS

PRODUCTS Contact Us

Contact Us