Bag filter

The bag filter is a dry filter device. It is suitable for capturing fine, dry, non-fibrous dust. The filter bag is made of woven filter cloth or non-woven felt, and the dust-containing gas is filtered by the filtering effect of the fiber fabric. When the dust-containing gas enters the bag filter, the dust with large particles and heavy specificity will be affected by gravity. The effect settles down and falls into the ash hopper. When the gas containing finer dust passes through the filter material, the dust is blocked, so that the gas is purified.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Overview

Product Description

The bag filter is a dry filter device. It is suitable for capturing fine, dry, non-fibrous dust. The filter bag is made of woven filter cloth or non-woven felt, and the dust-containing gas is filtered by the filtering effect of the fiber fabric. When the dust-containing gas enters the bag filter, the dust with large particles and heavy specificity will be affected by gravity. The effect settles down and falls into the ash hopper. When the gas containing finer dust passes through the filter material, the dust is blocked, so that the gas is purified.

The structure of the bag filter is mainly composed of upper box body, middle box body, lower box body (ash bucket), ash cleaning system and ash discharge mechanism.

Main feature

1.The dust removal efficiency is high, generally above 99%, the dust concentration of the gas at the outlet of the dust collector is within tens of mg/m3, and it has a higher classification efficiency for fine dust with sub-micron particle size.

2. The processing air volume has a wide range, the small one is only a few m3 in 1 minute, and the large one can reach tens of thousands of m3 in 1 minute. It is used for dust removal of industrial furnaces and kilns to reduce the emission of air pollutants.

3.Simple structure, convenient maintenance and operation.

4.Under the premise of ensuring the same high dust removal efficiency, the cost is lower than that of the electrostatic precipitator.

5. When using glass fiber, polytetrafluoroethylene, P84 and other high temperature resistant filter materials, it can operate under high temperature conditions above 200 ℃.

6.It is not sensitive to the characteristics of dust, and is not affected by dust and resistance.

Picture Example:

Lead Time:

| Quantity(Sets) | 1 - 5 | >5 |

| Est. Time(days) | 30 | To be negotiated |

Project show

Our equipments have exported to South Africa,India,Korea,India,Saudi Arabia,Indonesia, Malaysia, Loas, Vietnam,Dominician republic,Mongolia,Spain and other countries.

Delivery site of NPK fertilizer making equipments to Indonesia client

The installation site of NPK compound fertilizer making equipments

The installation site of annual capacity 30,000 tons NPK fertilizer project in Vietnam

Loading equipments to our clients

Our fertilizer projects in China and other countries

NPK and organic fertilizer project in Africa

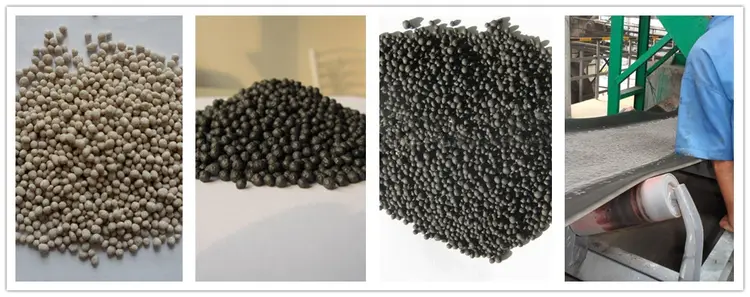

Final product produced by our machines:

Company Information

Shandong Reascend Machinery Co.,Ltd is one of Chinese professional fertilizer equipments manufacturers for over 30 years.We can produce NPK compound fertilizer production line, urea melt spraying granulation equipments line, Bulk Blending fertilizer (BB Fertilizer) equipment line, Organic fertilizer production line, and other fertilizer production lines.

And our fertilizer equipments have exported to South Africa,India,Korea,India,Saudi Arabia,Indonesia, Malaysia, Loas, Vietnam,Burundi,Dominician republic,Mongolia,Spain and other countries.

With a CAD design center and high-quality staff team,We could provide you the complete system from engineering,manufacturing fertilizer equipments, installation, commissioning, training local workers , fertilizer formula to after-sales services.

Our main equipments as following:

10000-200000 tons / year NPK compound fertilizer production line

30000-200000 tons / year urea melting spray granulation production line

50000-200000 tons/year sulfur-acid NPK granulation production line

10000-120000 tons/year controlled release fertilizer production line

50000-120000 tons / year high-tower fertilizer granulation production line

10000-300000 tons/year organic fertilizer production line

10000-300000 tons/year bulk blending fertilizer production line

10000-100000 tons/year superphosphate fertilizer production line

FAQ

1. Are you a manufacturer factory?

A: Yes, we are the professional manufacturer of the fertilizer machines for 30 years.

2. Could you provide the installation, commssioning, training or other kinds service?

A: Yes, we could arrange professional engineers to install the machines ,train your workers and test run the complate production line until your workers handle the operation; in addition ,we can supply the fertilizer fomulars for free.

3.Do you have customers near your factory, then can we visit the running fertilizer machines line?

A:Yes, there are many clients near our factory, we could take you to check the running fertilizer machines line.

4.Do you have experience in exporting, installing and traing the NPK fertilizer machines line in Africa, Southeast Asia, Middle East, South Asia, central Asia, Central America?

A:Yes, we have rich experience. Our fertilizer machines had exported to Saudi Arabia, India, Indonesia, South Africa, Nigeria, Dominica, Kazakhstan, Spain, Vietnam and other countries.

Contact Our Team

PRODUCTS CENTER

- Organic Fertilizer Equipment

- Compound Fertilizer Production Line

- Urea Production Plant

- Water Soluble/Controlled Release Fertilizer Equipment

- Blending Fertilizer Equipment

- Amino Acid Equipment

- Crushing Equipment/Mixing Equipment

- Granulation Equipment

- Rotary Dryer/Spray granulation dryer

- Rotary Cooler

- Fermentation Equipment

- Coating Machine/Screening Machine

- Dust Removal Equipment

- Auxiliary Equipment

CONTACT US

Contact Number

0086-18864836668

-

Sales Manager:

Johnny Cheung

-

Contact E-mail

-

Wechat

JohnnyZhang1987

-

Fax

86-0538-8761127

-

Address

Taishan Industrial Park, Tai'an City, Shandong Province

PRODUCTS

PRODUCTS Contact Us

Contact Us