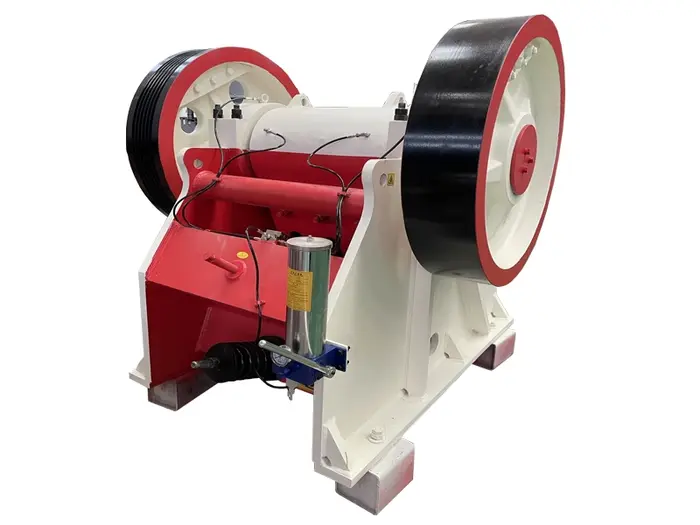

Jaw crusherjaw breaker

Jaw crusher is a common crushing equipment in mine crushing production. Its high compressive strength is 320MPa, which can meet the crushing processing of a variety of materials. It has the advantages of simple structure and reliable work.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Overview

Jaw crusher is a common crushing equipment in mine crushing production. Its high compressive strength is 320MPa, which can meet the crushing processing of a variety of materials. It has the advantages of simple structure and reliable work.

Applicable materials: river pebble, limestone, granite, basalt, quartzite, iron ore, dolomite, diabase, iron ore, gold ore, copper ore, etc.

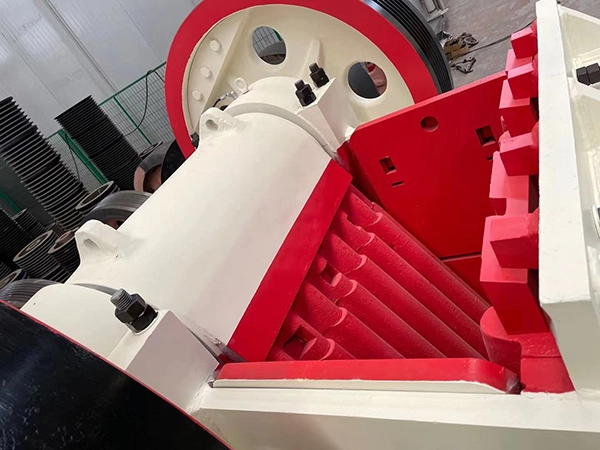

The jaw crusher adopts high-strength manganese steel and one-time molding casting. While achieving the ideal crushing effect such as large crushing ratio, high output and uniform product size, it has obvious advantages such as wear resistance, compression resistance and long life.

The crushing method of the jaw crusher is a curved extrusion type. The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw The plate approaches the fixed jaw plate, and the material is subjected to multiple crushing pressures such as squeezing, rubbing, and grinding; when the moving jaw moves downward, the angle between the toggle plate and the moving jaw becomes smaller, and the moving jaw plate leaves the fixed jaw under the action of the pull rod and spring. The jaw plate, at this time, the crushed materials are discharged from the lower mouth of the crushing cavity. With the continuous rotation of the motor, the crushing mobile jaw is periodically crushed and discharged to realize mass production.

Product advantages:

1. Special structure, high efficiency and environmental protection

The jaw crusher deepens the "V-shaped" deep cavity, high efficiency and energy saving, no dead corners in the crushing, uniform particle size of the finished product, and environmentally friendly equipment.

2. The quality of the movable jaw is reliable and the parts are good

The jaw crusher has a more advanced movable jaw assembly, which makes it more durable. The movable jaw assembly is composed of high-quality cast steel parts and is driven by two large cast steel flywheels. In addition, the heavy eccentric shaft also uses forging blanks. For processing, all this makes the jaw crusher reliable.

3. The rack can be dismantled and the failure rate is low

The frame can be disassembled and is not welded. It is sturdy and reliable, easy to transport and install, and has a lower failure rate.

4. Advanced manufacturing technology

Jaw crushers are generally made of high wear-resistant tooth plates, which are durable and efficient, and have a long service life.

technical parameter

Model | Feeding port size | Maximum feed size | Discharge opening adjustment range(mm) | Processing capacity(t/h) | Eccentric shaft speed(r/min) | Motor Power | Dimensions |

PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 4P 5.5 | 720×660×850 |

PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 910×750×990 |

PE-200×350 | 200×350 | 180 | 18-70 | 3-10 | 260 | 4P 11 | 1000×870×990 |

PE-250×400 | 250×400 | 210 | 20-60 | 5-21 | 300 | 6P 15 | 1300×1090×1270 |

PE-400×600 | 400×600 | 340 | 40-100 | 16-64 | 275 | 6P 30 | 1730×1730×1630 |

PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 6P 55 | 1980×2080×1870 |

PE-600×750 | 600×750 | 500 | 150-200 | 80-240 | 275 | 6P 55 | 2070×2000×1920 |

PE-600×900 | 600×900 | 500 | 65-160 | 50-160 | 250 | 6P 55 | 2190×2206×2300 |

PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 8P 110 | 2660×2430×2800 |

PE-900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 8P 110 | 3380×2870×3330 |

PE-1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 6P 160-220 | 4200×3300×3500 |

PE-1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 180 | 8P 280-355 | 5160×3660×4248 |

PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1200×1530×1060 |

PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 6P 22 | 1380×1750×1540 |

PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1560×1950×1390 |

PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 2140×1660×1500 |

PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2720×1950×1600 |

Contact Our Team

PRODUCTS CENTER

- Organic Fertilizer Equipment

- Compound Fertilizer Production Line

- Urea Production Plant

- Water Soluble/Controlled Release Fertilizer Equipment

- Blending Fertilizer Equipment

- Amino Acid Equipment

- Crushing Equipment/Mixing Equipment

- Granulation Equipment

- Rotary Dryer/Spray granulation dryer

- Rotary Cooler

- Fermentation Equipment

- Coating Machine/Screening Machine

- Dust Removal Equipment

- Auxiliary Equipment

CONTACT US

Contact Number

0086-18864836668

-

Sales Manager:

Johnny Cheung

-

Contact E-mail

-

Wechat

JohnnyZhang1987

-

Fax

86-0538-8761127

-

Address

Taishan Industrial Park, Tai'an City, Shandong Province

PRODUCTS

PRODUCTS Contact Us

Contact Us